The Role of LED Optics in Horticulture Lighting

LED grow lights have taken center stage in horticulture with the pursuit of optimized growth conditions and higher yields. They provide not only a customizable spectrum but also high energy efficiency, improving plant growth and yields. However, there is often an overlooked component: optics. The role of LED optics in horticultural lighting extends far beyond mere illumination. Optics have the ability to shape and direct light in ways that optimize coverage, minimize hotspots, and ensure uniform distribution across growing areas.

In this blog, we will explore what you need to know about LED optics and their role in horticultural lighting.

What is LED Optics

LED lights are directional, and they can illuminate at a maximum of 180 degrees. However, the light emitted from LEDs might not reach plants efficiently. That is where optics come in. LED optics are designed to manipulate and refine the output of light emitted by LED sources. These optical elements are strategically crafted to control the direction, distribution, and intensity of light, ensuring it reaches the plants with precision.

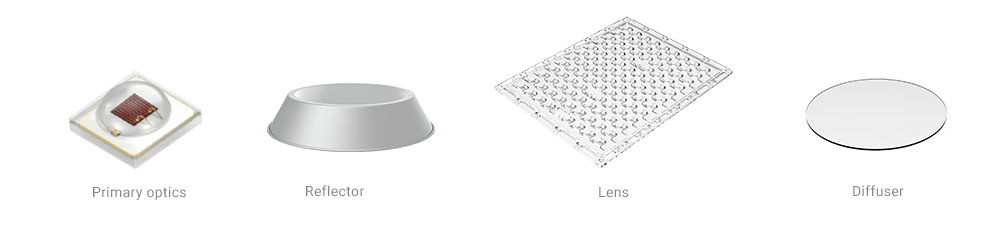

Types of LED Optics

There are two main types of LED optics: primary optics and secondary optics. Primary optics are built directly onto the LED chip while secondary optics are separate components that are placed in front of LEDs.

Primary optics

Primary optics are integrated into the LED package itself, and they determine the beam angle of a grow light. They are typically used to protect the LED diode and collimate the light emitted by the LED chip. Primary optics are the first step in managing the light output, bringing the light rays closer together to create a more focused beam.

Secondary optics

Secondary optics are separate components that are placed in front of the LED to further control the light distribution. They are made from a variety of materials, including glass, plastic, and metal.

Reflectors

Reflectors have highly reflective surfaces that redirect and shape the light emitted by LEDs, maximizing light output and ensuring optimal coverage. Reflectors are made of materials with high reflectivity such as aluminum or silver. They are also designed in various shapes, such as parabolic or elliptical, to achieve specific light patterns.

TIR optics

TIR (Total Internal Reflection) optics, or lenses, are the optical components that utilize the principle of total internal reflection to control the spread of light. TIR is a phenomenon where light traveling through a denser medium hits a boundary with a less dense medium at a specific angle. At this critical angle, all the light gets reflected back into the denser medium instead of refracting and escaping.

To shape the light effectively, TIR lenses are cone-shaped or have curved surfaces. As light travels through the TIR lens, it hits the internal surfaces at angles exceeding the critical angle, causing it to reflect back and forth within the lens.

Diffuser

Diffusers are used to scatter and soften light, resulting in a more uniform and evenly distributed illumination. They are normally made of frosted glass or translucent plastic. Diffusers are particularly useful in applications where glare is a concern.

Benefits of LED Optics in Horticulture Lighting

Although LEDs are more efficient than conventional light sources, LED lighting systems still need proper construction and design for beneficial effects on cultivation. The advanced LED optics of horticultural lighting systems provide higher precision, efficiency, and yields.

Light delivery on point

LED optics are designed to direct light precisely where it is needed, minimizing waste and reducing energy consumption. This targeted approach ensures that plants receive optimal light exposure without the excess cost.

Reduce energy waste

LED grow lights consume electricity to create light for plants. Without LED optics, grow lights may scatter light in unintended areas, leading to inefficient light distribution and energy waste. LED optics help maximize the conversion of electrical energy into usable light, contributing to significant energy savings.

Increase yields

Many LED grow lights are manufactured with a light spectrum in the PAR range to promote plant growth. However, it is useless if plants cannot receive the light. Through careful optical design, targeted, even, and consistent illumination across the growing areas leads to better plant growth and higher yields.

Optimized LED Optics Improves Yields

At Atop, we specialize in providing efficient LED grow lights tailored to meet our customers' goals. By leveraging advanced technology and expert lighting professionals, we ensure optimal performance and results.

For instance, our Horti-Rina inter canopy light is a prime example of our innovation. With a powerful 120W output and a unique 255° beam angle, it maximizes efficiency by reaching deep beneath the canopy, bathing every plant in light for optimal growth. The PC cover ensures even light diffusion and increased canopy penetration, resulting in boosted yields. One satisfied customer saw a remarkable 40% increase in yields when using our Horti-Rina to grow hemp.

Another standout product is our Horti-Drone quantum board light. Featuring a PC lens cover for enhanced reliability, it protects diodes from water and dust, making it ideal for humid environments without compromising performance.

As an OEM and ODM horticulture lighting solution provider, Atop is your trusted partner for all your lighting projects. Feel free to reach out to us for any assistance you may need.